Indicators on 24hr Media You Should Know

Indicators on 24hr Media You Should Know

Blog Article

The Only Guide for 24hr Media

Table of ContentsNot known Details About 24hr Media The Facts About 24hr Media RevealedRumored Buzz on 24hr MediaThe 2-Minute Rule for 24hr MediaHow 24hr Media can Save You Time, Stress, and Money.

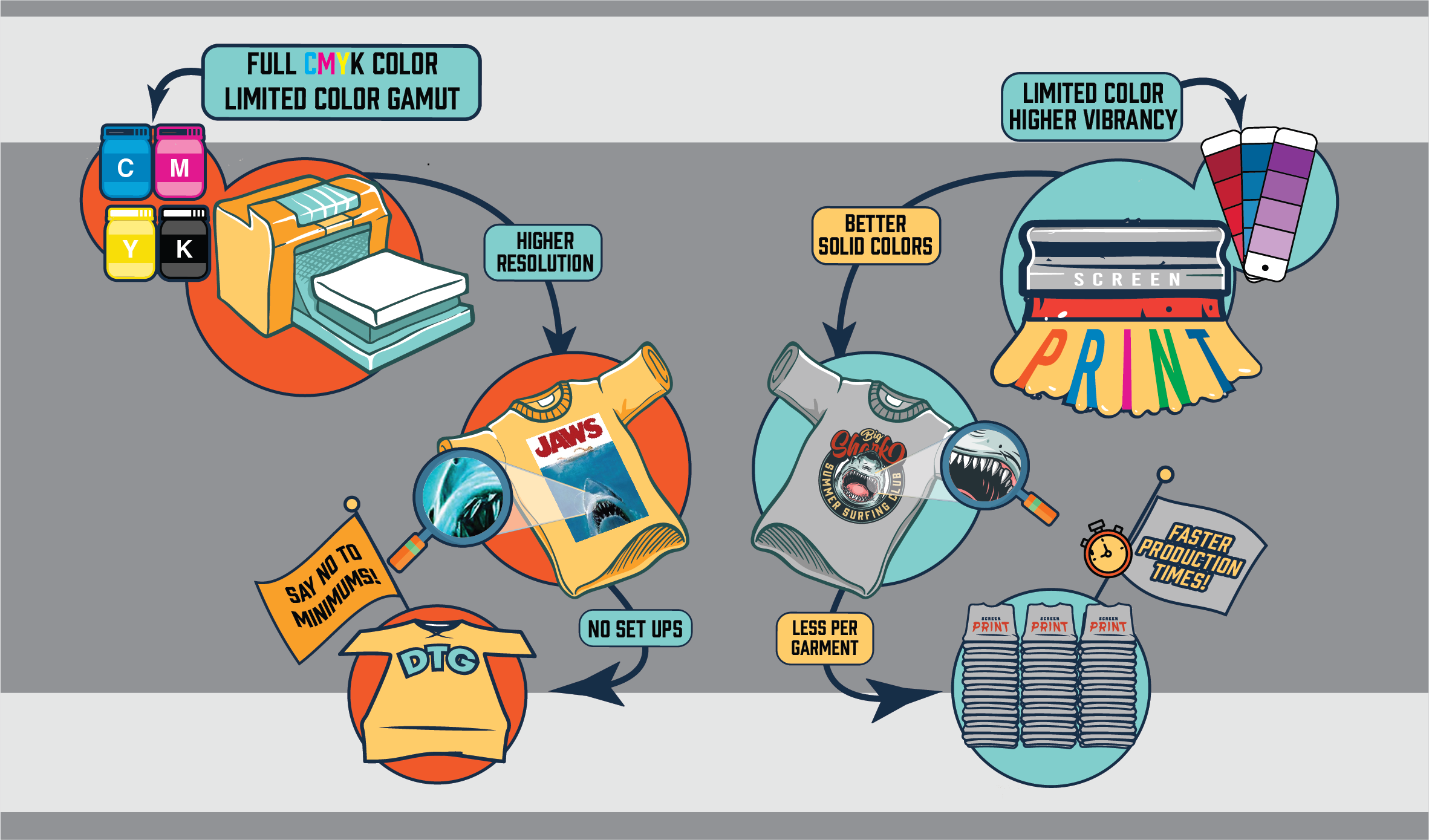

Offset, gravure printing and flexography are one of the most usual kinds of standard printing in the packaging room and each entails transferring the image from a plate to the surface area. To do this, first the plate needs to be developed, and it is the creation of these plates that take time, and set you back cash.According to PMMI, electronic printing allows brand names and makers to respond rapidly to client demands while enhancing the supply chain, lowering warehousing cost and waste, and delighting in faster time to market. That all noises terrific, but how does this technology do all that? The significant differentiator of these technologies is that there are no set up costs and no plates with electronic printing.

This results in quicker turnaround time and lowers price when using digital printing.

Fast production implies getting your item to market much faster. It additionally indicates it's much easier and faster to make adjustments later on, when you transform a dish, add a SKU, or produce seasonal product packaging. Digital printing is extremely versatile, so it's very easy to make changes to the bundle design quickly. It all returns to home plates.

24hr Media Can Be Fun For Everyone

A lot more stock can imply more waste in the future. With conventional printing methods, short-run printing is just not possible. Due to the fact that a great design can make or break your item, electronic printing consistently develops top quality, clear and colorful graphics each time. Digital printing on adaptable bags adds the bright, vibrant, and exact graphics that practically beckon customers to connect and touch them.

Filling ... Are you familiar with the benefits of digital printing? Both countered and digital printing have their place in the printing industry.

In this write-up, we will talk about the advantages of electronic printing to assist you better understand if digital printing is just what you require. Put simply - digital printing prints material straight onto the paper. It removes some steps needed in offset printing, like producing metal plates. Inkjet printers use little nozzles to spray droplets of ink onto the substrate.

Getting My 24hr Media To Work

As digital printing frequently progresses, it supplies extra opportunities and greater output high quality everyday. In some instances, the print quality can be as high as to balance out printing. As years go by, digital print is coming to be a lot more available, with improved rate and high quality. This is just the reason printing firms are adding digital printing to their deal.

For countered printing, if any blunder goes unnoticed prior to creating home plates, there will be a high price of producing a brand-new one. With digital printing, this is not the case (Digital Printing). Although everyone constantly wishes there will certainly be no errors, understanding the expense of remedying them if they occur is constantly a great concept.

This indicates each and every single item will certainly look the exact same, so the possibility you will need to dispose of any of them since of inconsistencies is low. Additionally, given that a proofing sample is printed on the same equipment as the item itself, color proofing is really precise. Any type of troubles with shade will show up on the evidence, and thus it will be feasible to alter it before printing the entire run.

All about 24hr Media

Digital printing, on the various other hand, needs very little setup. There are much less pre-press procedures, so the initial configuration time is substantially lowered. Consequently, turnaround is visibly much faster. Your order can be processed as quickly as you send it. This is fantastic when you remain in a rush to get your printed materials.

This implies more demands for digital on-demand print production. Every consumer appreciates a customized message. Among the advantages of digital printing is that customizing your marketing materials could not be less complicated. Cost-efficient, smaller sized sets permit businesses to tailor each order. Have a back-to-school sale? Make a flyer to target moms and dads and another one to target the students.

Digital printing is the perfect selection for variable information printing, like custom-made codes and addresses on direct-mail advertising. With digital printing, it is less problematic to make final changes to your layout. Sometimes the very best type of interaction is not electronic. In these Large Format Printing cases, relying upon electronic printing can ensure these orders have a minimal ecological impact.

How 24hr Media can Save You Time, Stress, and Money.

There is likewise no demand to clean up home plates after printing. The benefits of digital printing consist of that there is no waste from extra or remaining ink, paper, or chemicals because only what's required obtains printed. - for very short runs, electronic printing is the way to go, certainly.

Gone are the days of complicated setups and lengthy turn-around times - digital printing has actually revolutionised the print industry. The printing world has actually come a lengthy way since the days of Gutenberg's printing press. The brand-new typical is structured processes and cost-effective solutions for printing onto almost anything you can consider.

Report this page